Superhumans don't exist in the real world, but someday you might see super robots. Obviously, robots can be made that are stronger, faster, and better than humans, but do you think there is a limit to how much better we can make them?

Thanks to the ongoing developments in material science and soft robotics, scientists are now developing new technologies that could allow future robots to push the limits of non-human biology. For instance, a team of researchers at the University of Colorado Boulder recently developed a material that could give rise to soft robots capable of jumping 200 times above their own thickness. Grasshoppers, one of the most astonishing leapers on Earth, can leap into the air only up to 20 times their body lengths.

Despite outperforming the insects, the researchers behind the rubber-like jumping material say they took their inspiration from grasshoppers. Similar to the insect, the material stores large amounts of energy in the area and then releases it all at once while making a jump.

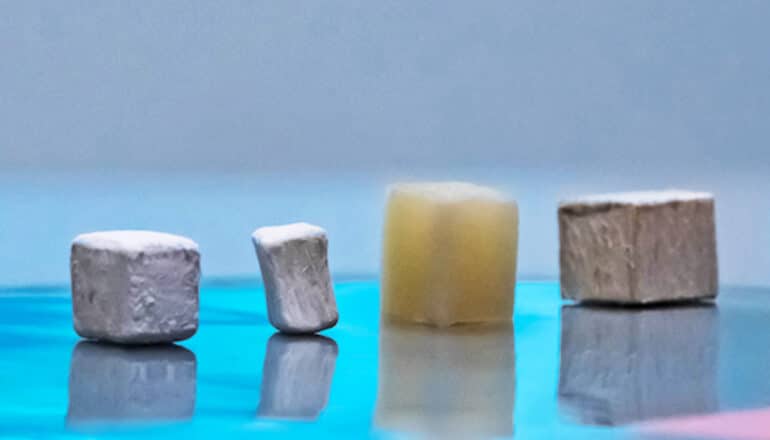

A new engineered wood traps carbon dioxide through a potentially scalable, energy-efficient process that also makes the material stronger for use in construction.

Structural materials like steel or cement come at a high cost both in dollars and carbon dioxide emissions; building construction and use accounts for an estimated 40% of emissions. Developing sustainable alternatives to existing materials could help mitigate climate change and reduce carbon dioxide emissions.

Working to address both issues at once, researchers found a way to incorporate molecules of a carbon dioxide-trapping crystalline porous material into wood.

“Wood is a sustainable, renewable structural material that we already use extensively,” says Muhammad Rahman, assistant research professor in materials science and nanoengineering at Rice University. “Our engineered wood did exhibit greater strength than normal, untreated wood.”

To achieve the feat, the network of cellulose fibers that gives wood its strength is first cleared out through a process known as delignification.

“Wood is made up of three essential components: cellulose, hemicellulose, and lignin,” Rahman says. “Lignin is what gives wood its color, so when you take lignin out, the wood becomes colorless. Removing the lignin is a fairly simple process that involves a two-step chemical treatment using environmentally benign substances. After removing the lignin, we use bleach or hydrogen peroxide to remove the hemicellulose.”

Next, the delignified wood is soaked in a solution containing microparticles of a metal-organic framework, or MOF, known as Calgary framework 20 (CALF-20). MOFs are high-surface-area sorbent materials used for their ability to adsorb carbon dioxide molecules into their pores.

“The MOF particles easily fit into the cellulose channels and get attached to them through favorable surface interactions,” says Soumyabrata Roy, a research scientist and lead author of the study in Cell Reports Physical Science.

MOFs are among several nascent carbon capture technologies developed to address anthropogenic climate change.

“Right now, there is no biodegradable, sustainable substrate for deploying carbon dioxide-sorbent materials,” Rahman says. “Our MOF-enhanced wood is an adaptable support platform for deploying sorbent in different carbon dioxide applications.”

“Many of the existing MOFs are not very stable in varying environmental conditions,” Roy says. “Some are very susceptible to moisture, and you don’t want that in a structural material.”

CALF-20, however, developed by George Shimizu, a professor at the University of Calgary, and his collaborators, stands out in terms of both performance level and versatility under a variety of environmental conditions, Roy says.

“The manufacturing of structural materials such as metals or cement represents a significant source of industrial carbon emissions,” Rahman says. “Our process is simpler and ‘greener’ in terms of both substances used and processing byproducts.

“The next step would be to determine sequestration processes as well as a detailed economic analysis to understand the scalability and commercial viability of this material,” he adds.

Shell Technologies and the UES-Air Force Research Laboratory supported the research.

Source: Rice University

The post Engineered wood gets stronger while trapping CO2 appeared first on Futurity.

New research shows how the atoms in perovskites move in response to light.

The breakthrough in visualization supports the researchers’ efforts to squeeze every possible drop of utility out of perovskite-based materials, including solar cells, a long-standing project that only recently yielded an advance to make the devices far more durable.

The study in Nature Physics details the first direct measurement of structural dynamics under light-induced excitation in 2D perovskites. Perovskites are layered materials that have well-ordered crystal lattices. They are highly efficient harvesters of light that are being explored for use as solar cells, photodetectors, photocatalysts, light-emitting diodes, quantum emitters, and more.

“The next frontier in light-to-energy conversion devices is harvesting hot carriers,” Aditya Mohite, a corresponding author of the study. “Studies have shown that hot carriers in perovskite can live up to 10-100 times longer than in classical semiconductors. However, the mechanisms and design principles for the energy transfer and how they interact with the lattice are not understood.”

Hot carriers are short-lived, high-energy charge carriers, either electrons for negative charges or electron “holes” for positive charges, and having the ability to harvest their energy would allow light-harvesting devices to “surpass thermodynamic efficiency,” says Mohite, an associate professor of chemical and biomolecular engineering in Rice University’s George R. Brown School of Engineering.

Mohite and three members of his research group, senior scientist Jean-Christophe Blancon and graduate students Hao Zhang and Wenbin Li, worked with colleagues at the SLAC National Accelerator Laboratory to see how atoms in a perovskite lattice rearranged themselves when a hot carrier was created in their midst. They visualized lattice reorganization in real time using ultrafast electron diffraction.

“Whenever you expose these soft semiconductors to stimuli like electric fields, interesting things happen,” Mohite says. “When you generate electrons and holes, they tend to couple to the lattice in unusual and really strong ways, which is not the case for classical materials and semiconductors.

“So there was a fundamental physics question,” he says. “Can we visualize these interactions? Can we see how the structure is actually responding at very fast timescales as you put light onto this material?”

The answer was yes, but only with a strong input. SLAC’s mega-electron-volt ultrafast electron diffraction (MeV-UED) facility is one of the few places in the world with pulsed lasers capable of creating the electron-hole plasma in perovskites that was needed to reveal how the lattice structure changed in less than a billionth of a second in response to a hot carrier.

“The way this experiment works is that you shoot a laser through the material and then you send an electron beam that goes past it at a very short time delay,” Mohite explains. “You start to see exactly what you would in a TEM (transmission electron microscope) image. With the high-energy electrons at SLAC, you can see diffraction patterns from thicker samples, and that allows you to monitor what happens to those electrons and holes and how they interact with the lattice.”

The experiments at SLAC produced before-and-after diffraction patterns that Mohite’s team interpreted to show how the lattice changed. They found that after the lattice was excited by light, it relaxed and literally straightened up in as little as one picosecond, or one-trillionth of a second.

Zhang says, “There’s a subtle tilting of the perovskite octahedra, which triggers this transient lattice reorganization towards a higher symmetric phase.”

By demonstrating that a perovskite lattice can suddenly become less distorted in response to light, the research showed it should be possible to tune how perovskite lattices interact with light, and it suggested a way to accomplish the tuning.

Li says, “This effect is very dependent on the type of structure and type of organic spacer cation.”

There are many recipes for making perovskites, but all contain organic cations, an ingredient that acts as a spacer between the materials’ semiconducting layers. By substituting or subtly changing organic cations, researchers could tailor lattice rigidity, dialing it up or down to alter how the material responds to light, Li says.

Mohite says the experiments also show that tuning a perovskite’s lattice alters its heat-transfer properties.

“What is generally expected is that when you excite electrons at a very high energy level, they lose their energy to the lattice,” he says. “Some of that energy is converted to whatever process you want, but a lot of it is lost as heat, which shows in the diffraction pattern as a loss in intensity.

“The lattice is getting more energy from thermal energy,” Mohite says. “That’s the classical effect, which is expected, and is well-known as the Debye-Waller factor. But because we can now know exactly what’s happening in every direction of the crystal lattice, we see the lattice starts to get more crystalline or ordered. And that’s totally counterintuitive.”

A better understanding of how excited perovskites handle heat is a bonus of the research, he says.

“As we make devices smaller and smaller, one of the biggest challenges from a microelectronics perspective is heat management,” Mohite says. “Understanding this heat generation and how it’s being transported through materials is important.

“When people talk about stacking devices, they need to be able to extract heat very fast,” he says. “As we move to new technologies that consume less power and generate less heat, these types of measurements will allow us to directly probe how heat is flowing.”

The research had support from the Department of Energy, the Office of Naval Research, the Robert A. Welch Foundation, and the Academic Institute of France.

Source: Rice University

The post Team sees light make atoms ‘dance’ in perovskites appeared first on Futurity.

Nobody starts a hardware company with the express goal of destroying as much of the planet as they possibly can. Walking around the startup hall at CES, however, I noticed that — with a few notable exceptions — there was painfully little attention given to material choice, repairability, ease of disassembly and considerations around the end of usable life.

It’s embarrassing, really — but as someone who used to run a hardware startup, I know it can be hard to prioritize when you have limited time and resources. However, if you can’t make planet-friendly choices as the founder of a startup, when the buck literally stops with you, when can you?

In an effort to figure out how you can create greener hardware, we spoke with Lauryn Menard, a professor at the California College of the Arts, where she teaches the future of biodesign. She’s also an adviser to Women in Design SF and the co-founder and creative director at PROWL Studio, an Oakland, California-based design and material futures consultancy focusing on sustainable solutions.

“As a startup, you have choices. The thing is, it’s such a capitalistic society we live in, and a lot of decisions are made based on time and money,” Menard explained. The startups want to think about sustainability, but they are moving at breakneck speed and trying to get a product to market as soon as possible. “The startups need to hit their target price point and all that good stuff.”

“You don’t have to adopt a new bioplastic, you can instead choose something that already exists: Not everything has to be made from a new freaking material!” Lauryn Menard

But there are some big things moving out there in the market. Consumer demands are shifting, and climate pledges, circularity strategies and environmental questions are all bubbling to the surface. It’s hard to say whether enough customers are making purchasing decisions based on a company’s green credentials to move the needle meaningfully, but product development cycles can take years, and who knows what the landscape looks like by the time your product makes it to market? To some companies, it might make sense to take the risk, but other founders are starting to think differently about how products are made.

“If a startup is being run by solely engineers, that can be problematic: Engineers tend to be worried [about] making sure they’re getting to the finish line. They put all of their energy into making something function and are probably leaning toward materials, ways of making and manufacturing processes that they’re already familiar with,” Menard explained. “What we’ve seen [be] really helpful is working with a design studio that specializes in more sustainable ways of thinking and healthier materials. Or partnering with someone like a materials library, so they’ve already started thinking about the functionality of the materials by the time they are making a prototype. Just in the same way that it takes a really long time to get an MVP product that works and looks the way you want, it sometimes takes a long time to put a new material into an existing manufacturing process.”

One of the big challenges we have with creating more sustainable products is that we are often replacing plastics with something else. The problem is that plastics are deeply embedded in workflows already. Product designers love how predictable, easy to design and repeatable plastic is.

There also isn’t an obvious one-for-one replacement for plastic; depending on the use case and material properties you need, you may have to replace it with wool, paper, wood, plant pulp, carbon fiber, seaweed, hemp, mycelium, lab-grown leather or any number of other materials that are available.

Here’s what founders and product designers can do to think about sustainability and product development in a more conscious way.

Startups, here’s how you can make hardware without ruining the planet by Haje Jan Kamps originally published on TechCrunch

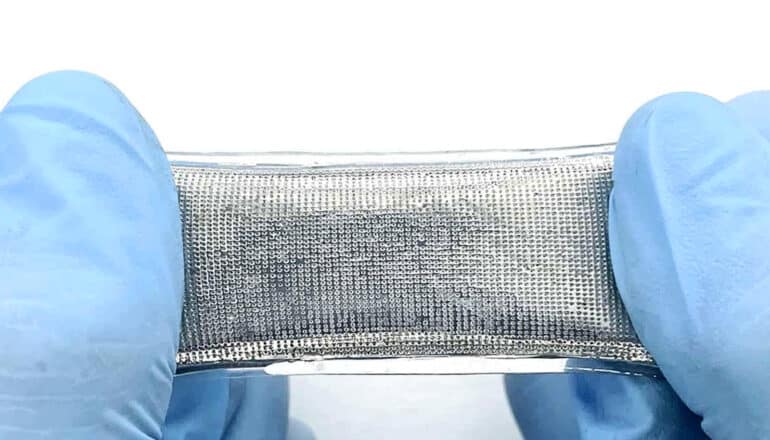

A new technique uses liquid metal to create an elastic material that is impervious to both gases and liquids.

Applications for the material include flexible batteries and other packaging for high-value technologies that require protection from gases.

“This is an important step because there has long been a trade-off between elasticity and being impervious to gases,” says Michael Dickey, professor of chemical and biomolecular engineering at North Carolina State University.

“Basically, things that were good at keeping gases out tended to be hard and stiff. And things that offered elasticity allowed gases to seep through. We’ve come up with something that offers the desired elasticity while keeping gases out.”

The new technique makes use of a eutectic alloy of gallium and indium (EGaIn). Eutectic means that the alloy has a melting point that is lower than its constituent parts. In this case, the EGaIn is liquid at room temperature.

The researchers created a thin film of EGaIn, and encased it in an elastic polymer. The interior surface of the polymer was studded with microscale glass beads, which prevented the liquid film of EGaIn from pooling. The end result is essentially an elastic bag or sheath lined with liquid metal, which does not allow gases or liquids in or out.

The researchers tested the effectiveness of the new elastic material by assessing the extent to which it allowed liquid contents to evaporate, as well as the extent to which it allowed oxygen to leak out of a sealed container made of the material.

“We found that there was no measurable loss of either liquid or oxygen for the new material,” says Tao Deng, professor at Shanghai Jiao Tong University and co-corresponding author of the study in the journal Science.

The researchers are also conscious of costs associated with manufacturing the new material.

“The liquid metals themselves are fairly expensive,” Deng says. “However, we’re optimistic that we can optimize the technique—for example, making the EGaIn film thinner—in order to reduce the cost. At the moment, a single package would cost a few dollars, but we did not attempt to optimize for cost so there is a path forward to drive cost down.”

The researchers are currently exploring testing options to determine whether the material is actually an even more effective barrier than they’ve been able to show so far.

“Basically, we reached the limit of the testing equipment that we had available,” Dickey says.

“We’re also looking for industry partners to explore potential applications for this work. Flexible batteries for use with soft electronics is one obvious application, but other devices that either use liquids or are sensitive to oxygen will benefit from this technology.”

Additional coauthors are from Shanghai Jiao Tong University and NC State.

The National Science Foundation, the National Natural Science Foundation of China, the Innovation Program of the Shanghai Municipal Education Commission, and Shanghai Jiao Tong University supported the work.

Source: NC State

The post Elastic material could protect flexible batteries from gases appeared first on Futurity.